Learn more about Japanese arts & crafts. See Our Instagram ・ @JapanCraft21

【Research about Traditional Japanese Crafts】

アットゥシ Attus

Attus is a traditional Ainu textile. The inner bark of the ohyō elm is stripped away, softened by soaking in water, and then peeled into even thinner strips. These thin strips are dyed using vegetable dyes, separated with the fingers, and twisted into thread. The fabric is woven using a primitive, frameless loom–called a backstrap loom–in which the ends of the warp are fixed to a pillar or the like with the tension of the threads adjusted using the hips and the body. The result is light, durable, and gentle to the touch.

アットゥシは伝統的なアイヌの織物です。オヒョウの木の内皮からとった繊維から糸を紡ぎ、織られています。軽く、丈夫で、優しい肌触りが特徴です。

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【日本伝統工芸再生コンテスト 受賞者作品展】

ジャパン・クラフト 21の使命は、消滅の危機にある日本の伝統工芸を見出し、明確な戦略のもとに有効な対策を講じ、伝統工芸の世界の再生化を支援することです。

第4回目となる本作品展では、クラフトリーダー2024 6組の作品が並びます。ぜひお越しください。

日時:2026年2月13日(金)〜20日(金) 11:00-18:00

出展作家(順不同、敬称略):

前田雄亮

大滝ジュンコ

MUJUN Workshop

坂井直樹

高松太一郎

光をまとう

場所:銀座一穂堂

東京都中央区銀座1-8-17 伊勢伊ビル3F

・有楽町線 銀座一丁目駅 7番出口ポーラビル向かい

・日比谷線、銀座線、丸の内線 銀座駅 A13番出口から徒歩3分

@ippodogallerytokyo

※16日(月)は3Fギャラリー休廊です。B1Fの本作品展のみ開催となります。

#japancraft21 #japan #kogei

#Craftexhibitions

【Craft Leader】Hiraku SUDO

Metal Work / Kyoto

A metal arts craftsman of the highest caliber, Sudo began his career by studying with a sixth generation metal master in Kyoto. After establishing his own independent studio a decade ago, he has continued growing his skills by challenging himself to repair nearly 1500 vastly different antique Japanese masterworks, one after another. These repairs demanded significant research since many original fabrication methods had long been lost. This demanding and meticulous repair work has, in turn, helped him develop an intimate understanding of the techniques used by the hundreds of master artisans who created those works. Today, Sudo applies his rarefied expertise and unique understanding of Japanese aesthetics to create original works of functional artist crafts. Sudo is committed to applying his vast knowledge and the honing of his creative skills in order to advance traditional metal craft decorative techniques for the 21st century.

@kushin_31

#japancraft21 #japan #kogei #craft

Part of a series of works using various rarefied metal-working techniques to create tea caddies for the Way of Tea that mimic intricate silk weaving processes.

—

- Japanese metal crafts are especially prized for their precision, durability, and artistic beauty.

- Japanese metalworking dates back over two millennia, originally for the creation of farm tools. Later, it came to include samurai swords, food cutlery and both decorative and functional items.

- Sand Casting: Molten metal is poured into molds made from silica-rich sand to create such things as Buddhist temple bells and early statuary.

- Fukiwake: Various artistic patterns can be achieved by carefully timing the pouring of contrasting kinds of molten metal into a mold.

- Forge welding is a tool-making process where two different kinds of metal are heated and hammered into one. (most commonly high-carbon steel and iron.)

- Hammering technique transforms pieces of metal into thin sheets.

- Shibori relies on anvils, against which thin metal sheets are hammered into various shapes.

- Horimono is an engraving process that adds artistic appeal. It can also serve to lighten or enhance blade balance in sword-making.

@kushin_31

#japancraft21 #japan #kogei #craft

Part of a series of works using various rarefied metal-working techniques to create detailed replicas of various insects, with both moving joints and wings. This is a kind of wasp.

—

- Japanese metal crafts are especially prized for their precision, durability, and artistic beauty.

- Japanese metalworking dates back over two millennia, originally for the creation of farm tools. Later, it came to include samurai swords, food cutlery and both decorative and functional items.

- Sand Casting: Molten metal is poured into molds made from silica-rich sand to create such things as Buddhist temple bells and early statuary.

- Fukiwake: Various artistic patterns can be achieved by carefully timing the pouring of contrasting kinds of molten metal into a mold.

- Forge welding is a tool-making process where two different kinds of metal are heated and hammered into one. (most commonly high-carbon steel and iron.)

- Hammering technique transforms pieces of metal into thin sheets.

- Shibori relies on anvils, against which thin metal sheets are hammered into various shapes.

- Horimono is an engraving process that adds artistic appeal. It can also serve to lighten or enhance blade balance in sword-making.

@kushin_31

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

奈良墨 Nara Sumi

Nara ink, with a history dating back 1,300 years to the Tempyo era, is a traditional industry that represents Nara. Known as “Nanto Soot Ink,” it originated from oil-based ink made at Nitaibo of Kofukuji Temple during the Muromachi period. Although ink production spread across various regions during the Edo period, many skilled craftsmen gathered in Nara due to its advanced techniques, making Nara the leading production area, with around 90% of the national market share for ink.

奈良の墨は古く天平時代から1300年の歴史をもつ奈良を代表する伝統産業です。奈良の墨は「南都油煙墨」と呼ばれ、室町時代に興福寺の二諦坊で作られた油墨が起源とされます。 江戸時代に入ると各地で製造されましたが、技術の高い奈良に多くの職人が集まったため、奈良は全国シェア約90%を誇る墨の主要産地となりました。

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Kazuya NANJO

Bells / Kyoto

Expanding the appeal of traditional Buddhist bells to a broader audience with A passionate commitment to excellence without compromise. One of only two or three remaining bell makers who insist on hand craftsmanship, he is bringing his 200-year old family business into the 21st century with new products for modern living that transcends religious use to include the worlds of art and music as well as activities that support mental well-being. Having already applied to develop a new generation of Buddhist altar bells with a unique tone, By re-invigorating both the craft and the market, we hope to ensure the longevity of traditional bells for future generations of users and makers alike.

@linne_orin

#japancraft21 #japan #kogei #craft

A new version of traditional Buddhist Orin bowls (bells). By suspending the bell, this design enhances its clear tone and beautifully long-lasting reverberation. It also features a design suited to modern lifestyles, offering new possibilities for how the Orin can be used beyond traditional contexts.

—

Orin bowls (bells) have been made in Japan since the 500s, when the methodology came from China. They are cast as a mixture of molten bronze and tin are poured into clay molds, which give shape to both the inner and outer bell. This alloy results in a durable bell with a beautiful sound. Bronze is a soft metal and tin is hard. The hardness of the bell can vary depending on the percentage of the two metals in the blend. The harder the bell, the clearer the sound and the longer the reverberation.

Traditional handmade molds are made by combining sand, clay, and rice husks, resulting in a somewhat porous mold with good airflow that avoids shape and sound-distoring gasses that may become trapped. The molds are then fired in a ceramics kiln.

The combination copper and tin alloy is heated to 1300 degrees C. before being poured into the pre-fired molds.

After cooling, the orin are removed by breaking up the clay molds. Then, each bowl is individually and precisely hand-shaped by carving and polished using a lathe. Craftspeople are careful to minimize the amount of carving so as not to diminish the sound of the bell. Furthermore, attention is paid to monitoring weather conditions and humidity, which can negatively influence the quality of sound.

@linne_orin

#japancraft21 #japan #kogei #craft

During the time of the fifth-generation master, Kanzaburo Nanjo, extensive independent research was conducted to further enhance the sound quality of the Orin. This led to the optimization of the alloy composition known as "Sahari", a blend of copper and tin used as the primary material for casting. The resulting formula has been passed down through generations and ultimately gave rise to the “Kanzaburo Orin”, now considered the signature piece of Nanjo Kobo.

—

Orin bowls (bells) have been made in Japan since the 500s, when the methodology came from China. They are cast as a mixture of molten bronze and tin are poured into clay molds, which give shape to both the inner and outer bell. This alloy results in a durable bell with a beautiful sound. Bronze is a soft metal and tin is hard. The hardness of the bell can vary depending on the percentage of the two metals in the blend. The harder the bell, the clearer the sound and the longer the reverberation.

Traditional handmade molds are made by combining sand, clay, and rice husks, resulting in a somewhat porous mold with good airflow that avoids shape and sound-distoring gasses that may become trapped. The molds are then fired in a ceramics kiln.

The combination copper and tin alloy is heated to 1300 degrees C. before being poured into the pre-fired molds.

After cooling, the orin are removed by breaking up the clay molds. Then, each bowl is individually and precisely hand-shaped by carving and polished using a lathe. Craftspeople are careful to minimize the amount of carving so as not to diminish the sound of the bell. Furthermore, attention is paid to monitoring weather conditions and humidity, which can negatively influence the quality of sound.

@linne_orin

#japancraft21 #japan #kogei #craft

To fully bring out the unique qualities of the ”Sahari" alloy, Nanjo Kobo continues to practice the traditional ”yaki-gata” casting method, in which molds are fired using wood. Nanjo Kobo is now the only workshop in Japan that still produces Orin using this time-honored technique.

—

Orin bowls (bells) have been made in Japan since the 500s, when the methodology came from China. They are cast as a mixture of molten bronze and tin are poured into clay molds, which give shape to both the inner and outer bell. This alloy results in a durable bell with a beautiful sound. Bronze is a soft metal and tin is hard. The hardness of the bell can vary depending on the percentage of the two metals in the blend. The harder the bell, the clearer the sound and the longer the reverberation.

Traditional handmade molds are made by combining sand, clay, and rice husks, resulting in a somewhat porous mold with good airflow that avoids shape and sound-distoring gasses that may become trapped. The molds are then fired in a ceramics kiln.

The combination copper and tin alloy is heated to 1300 degrees C. before being poured into the pre-fired molds.

After cooling, the orin are removed by breaking up the clay molds. Then, each bowl is individually and precisely hand-shaped by carving and polished using a lathe. Craftspeople are careful to minimize the amount of carving so as not to diminish the sound of the bell. Furthermore, attention is paid to monitoring weather conditions and humidity, which can negatively influence the quality of sound.

@linne_orin

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

土鈴 Dorei

Dorei are clay bells, often shaped like animals or auspicious symbols. These hand-crafted bells are made from clay and fired to create a unique, resonant sound.

Dorei are typically used as talis- mans to bring good fortune, ward off evil spirits, and promote prosperity. They are commonly hung in homes, gardens, or shrines and are popular gifts during festivals and special occasions. The charming designs and pleasant chimes of Dorei make them a beloved element of Japanese folk art.

鳥取の伝統工芸品。

土鈴の歴史は大変古く、はるか縄文時代までさかのぼります。古来より、魔除けの力を持つといわれ、祭礼用に用いられてきたようです。現在では、ふるさとの歴史や祭礼縁起など地域にちなんだ土鈴や、干支の土鈴などをひとつひとつ手作りで制作しています。土鈴のコレクターの方々にも幅広く人気があり、地域の情報発信にも役立っています。

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Tatsuma SHOJI

Japanese Ceramic Rooftiles / Kyoto

We intend to broaden the base of our "KAWARA" brand of Japanese ceramic rooftiles for the luxury, custom home market both in Japan and abroad. In so doing, we want to help restore Japanese cultural identity through brilliant traditional-based Japanese architecture. In addition to production technique, our personal and direct involvement at the jobsite is central to our branding concept.

@daibutsu.co.ltd

#japancraft21 #japan #kogei #craft

1.Ceramic roof tiles that would typically cover the main hall of a Buddhist Temple.

2.A close-up view of parapet wall rising above and separating two sections of a ceramic tile roof.

—

Ceramic kawara roof tiles have been produced in Japan since the 500s. Because they are kiln-fired at temperatures at or above 1200 degrees C, they have exceptional longevity compared to tiles fired at much lower temperatures. Benefits from high-temperature firing include increased longevity, where they last more than 100 years with little maintenance, high durability, the ability to resist heavy rain, snow, and wind as well as extreme fluctuations in temperature, and the ability to resist algae and fungus. Fabricated from only natural materials, tile roofs can insulate interior temperatures up to 30% in both summer and winter and when installed correctly, they can resist considerable earthquake activity. In addition to roof tiles, high-fired kawara tiles can be installed as both walls and floors.

KUNKAKU - Wall tile that enhances architectural design

This innovative product combines the appeal of traditional smokey glaze roof tiles with contemporary design. The depth and sensibility created by the cushion pattern result in a sophisticated look for the entire space.

Harmoniously combining tradition and modern design refines our notion of “heavy” roof tiles as a light, modern building material.

@daibutsu.co.ltd @tatsuma_shoji1126

#japancraft21 #japan #kogei #craft

【Zoom presentation】

Explore the evolution of Japan’s most celebrated ceramic artists from the postwar era to today. Discover representative works by internationally acclaimed masters and experience the remarkable breadth and depth of this world-class artistic tradition.

・Date & Time:

ーNorth America West Coast: Monday, January 26, 5 pm

ーNorth America East Coast: Monday, January 26, 8 pm

ーJapan: Tuesday, January 27, 10 am

Regiser here

https://forms.gle/Sc8BAxXy43Jd7yES9

1.A traditional style entry gate with a ceramic tile roof.

2.The ornamental end caps of rooftiles, visible from the perifery of a structure.

—

Ceramic kawara roof tiles have been produced in Japan since the 500s. Because they are kiln-fired at temperatures at or above 1200 degrees C, they have exceptional longevity compared to tiles fired at much lower temperatures. Benefits from high-temperature firing include increased longevity, where they last more than 100 years with little maintenance, high durability, the ability to resist heavy rain, snow, and wind as well as extreme fluctuations in temperature, and the ability to resist algae and fungus. Fabricated from only natural materials, tile roofs can insulate interior temperatures up to 30% in both summer and winter and when installed correctly, they can resist considerable earthquake activity. In addition to roof tiles, high-fired kawara tiles can be installed as both walls and floors.

KUNKAKU - Wall tile that enhances architectural design

This innovative product combines the appeal of traditional smokey glaze roof tiles with contemporary design. The depth and sensibility created by the cushion pattern result in a sophisticated look for the entire space.

Harmoniously combining tradition and modern design refines our notion of “heavy” roof tiles as a light, modern building material.

@daibutsu.co.ltd @tatsuma_shoji1126

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

ぽっぺん Poppenn

Nagasaki became a major center for glass-blown handcrafts more than 400 years ago. One of the city’s most unique glass products is the poppen. These glass toys were traditionally blown on New Year's Day to get rid of bad luck for the year. As the name suggests, when a person blows air into the glass tube, the bottom of the glass bulb depresses with a "pop" sound, and when the pressure is released, the bulb returns to its original shape, making a "pen" sound. Poppen come in a variety of delightful colors and shapes, and each produces a different tone.

400年以上も前、長崎は日本における吹きガラス工芸の中心地となりました。(長崎のガラス製品は、ポルトガル語でガラスを意味する「ビードロ」と呼ばれることが多いです。)この街で最もユニークなガラス工芸品の一つが、ポッペンです。このユニークなガラスのおもちゃは、新年にその年の厄を払うために伝統的に吹き飛ばされていました。その名の通り、ガラス管に息を吹き込むと、ガラス球の底が「ポン」という音とともに下がり、圧力が抜けると元の形に戻り、「ペン」という音がします。ポッペンは様々な色と形があり、それぞれ異なる音色を奏でます。

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Yohko TODA + the edit

Urushi Lacquer・ Kyoto

'I consider the almost divine beauty and purity of Urushi is at its acme at the instant the liquid is brushed on. Imagine the moment the tip of the human haired brush puts down Urushi as if it were a thousand strands of flowing glistening black hair. Imagine the very moment Urushi transforms an object into an unfathomable, visceral, giddying black. Though freshly dried Urushi shines with the lucidness of a newborn, the excitement gradually subsides and silence follows. Once it drys, the vividness is no longer. From there Urushi gradually hardens over a 6-month period. In a somewhat lonesome sentiment, the Urushi comes of age I guess. From this point of view, liquid Urushi possesses red hot lava-like chaotic energy and vigor. The beauty and spiritualism Urushi with which it has enamored people from the ancient times has many faces. When facing Urushi, my body rejoices in a storm of excitement. Sometimes my heart aches, other times experience ecstasy. Sometimes dumbfounded, nearly fainting, and crying without knowing. Thus I found my vocation to pass along the fascination of live Urushi through multiple dimensions and perspective. 3D, 2D, space, time, concept, etc.

the edit -Yuki Kajikawa the edit is a brand by Yuki Kajikawa, curator at the Kahitsukan, Kyoto Museum of Contemporary Art. Throughout my career, I have fostered many connections with artists whose ideas and materials have provided me with a wealth of inspiration. the edit was conceived as a brand of products with stories based on these meaningful encounters. The concept stems from the myth of the red thread; a bond between people destined to be soulmates, regardless of place, time, or circumstance, that stretches or tangles but never breaks. Life is full of unexpected coincidences. Inspired by the red thread, I hope this series of carefully edited items will add color to your life.' Yohko Toda

@yokunettete @theeditkyoto

#japancraft21 #japan #kogei #craft

Collaboration work with Yuki Kajikawa/Curator of Kahitsukan-Kyoto Museum of Contemporary Art, Director of the edit

‘the capsule began as a message capsule created by lacquer artist Yohko Toda. Upon seeing her work for the first time, I imagined her piece sheltering my last convictions as I leave this world behind. This evolved into the idea of designing a vessel for “unfulfilled communication.” I wanted to create a mystical mailbox that could deliver thoughts beyond space and time to people out of reach or even to the departed.

I had many discussions with Yohko for over a year. We explored the possibilities and limitations of handcrafted metal materials and the struggles between technology and design. We were very particular about the shape not being a tube and its ability to seal properly. the capsule (2022) is the result of our collaboration, a piece that may unfold into something new in the future.’ Yuki

'With the direction of Yuki Kajikawa, the message capsule underwent a happy transformation. First of all, the capsule, which had been lying down, stood up. Similar to the flame of a candle, the smoke of an incense stick or a prayer on its way to the heavens. Rather than having a practical use, Yuki’s wish was for the message capsule to hold a letter conveying her feelings

I usually use tin as a material combined with a thick layer of “urushi”. Tin is soft in texture yet sturdy. The combination of metal and lacquer was used for armors and other items throughout history, as lacquer prevents metal corrosion. This time, vermillion lacquer was applied on both the inside and the outside of the capsule. The outer veneer acts as a shield while the inner layer protects the feelings. Even if the tin tarnishes over time, it remains vermilion. I believe the capsule can preserve feelings connected by the red thread, transcending time and space. ' Yohko

@yokunettete @theeditkyoto

#japancraft21 #japan #kogei #craft

As Urushi forms a sexy and attractive coating, I let it freely form itself in this piece. This vessel images an organic, almost membraneous embrace within.

2009 Gold prize at The Ishikawa International Urushi Exhibition 2009

Technique: Kanshitsu (dry lacquer), Shu-urushinuri (vermillion lacquer)

size: H270㎜×W640mm×D430㎜

Japanese Urushi lacquer, hemp cloth, tonoko, jinoko vermillion

—

Urushi 漆, a completely natural lacquer coating, has been in use in Japan for 9,000 years. It is the world’s hardest and most durable coating, and can be applied to wood, metal, bamboo, glass, even over hemp cloth (known as “dry lacquer”). Not only it is a protective coating but it has anti-bacterial properties, is easy to clean, and increases the longevity of whatever it is applied to. Clear urushi coating on wood appears more lustrous and beautiful over time, and the wood grain becomes more prominent.

The clear, honey-colored sap from the lacquer tree (Rhus vernacifera) is collected by hand from incisions on the tree trunk; total output of the precious substance which can ever be extracted from one tree is only six ounces (177 cc). Mineral pigments can be added to create any color, such as iron oxide for black urushi or red iron oxide for red urushi.

During the Heian period (792 - 1185), lacquer-coated wooden functional ware was very popular and Japan became Asia’s undisputed lacquer master during the Golden Age of lacquerware which followed. The Portuguese introduced it to the west in the 16th century and it was widely spread in the 17th century by the Dutch East India Company, enthralling royalty and nobility alike. Marie Antoinette amassed a famous collection of lacquerware items. Japanese urushi ware dazzled the west as Japanism spread during the Belle Époque.

Mother-of-pearl inlay is a process of embedding pieces taken from the iridescent inner layer of mollusk shells (abalone or oyster shell, etc.) into urushi. The pieces of shell are arranged in decorative motifs and most often cover a wooden base. The Japanese adopted this methodology from the Chinese in about the 7th century CE.

@yokunettete @theeditkyoto

#japancraft21 #japan #kogei #craft

【Zoom presentation】

Join Steve Beimel for a brand new live Zoom presentation:

"Introduction to the Masterworks of 25 Japanese Ceramics Superstars, Part III (Artists 50–75)."

Explore the evolution of Japan’s most celebrated ceramic artists from the postwar era to today. Discover representative works by internationally acclaimed masters and experience the remarkable breadth and depth of this world-class artistic tradition.

・Date & Time:

ーNorth America West Coast: Monday, January 26, 5 pm

ーNorth America East Coast: Monday, January 26, 8 pm

ーJapan: Tuesday, January 27, 10 am

・Registration:

https://forms.gle/Sc8BAxXy43Jd7yES9

#japancraft21 #japan #kogei

NHK world Japan で放送されましたバイメルが出演するCore Kyoto が以下URLからご視聴いただけます。

見逃された方はぜひご覧ください。

https://www3.nhk.or.jp/nhkworld/en/shows/2029241/

Foreign Residents: Infusing New Life into Tradition

Many foreigners make Kyoto their home and bring innovation to traditional culture. Their creativity and global perspective spark revitalization and inspiration as they breathe new life into the city.

- Fabric made by a kimono producer who enjoys support from American Steve Beimel.

#japancraft21 #japan #kogei #craft

#nhk @nhkworldjapan

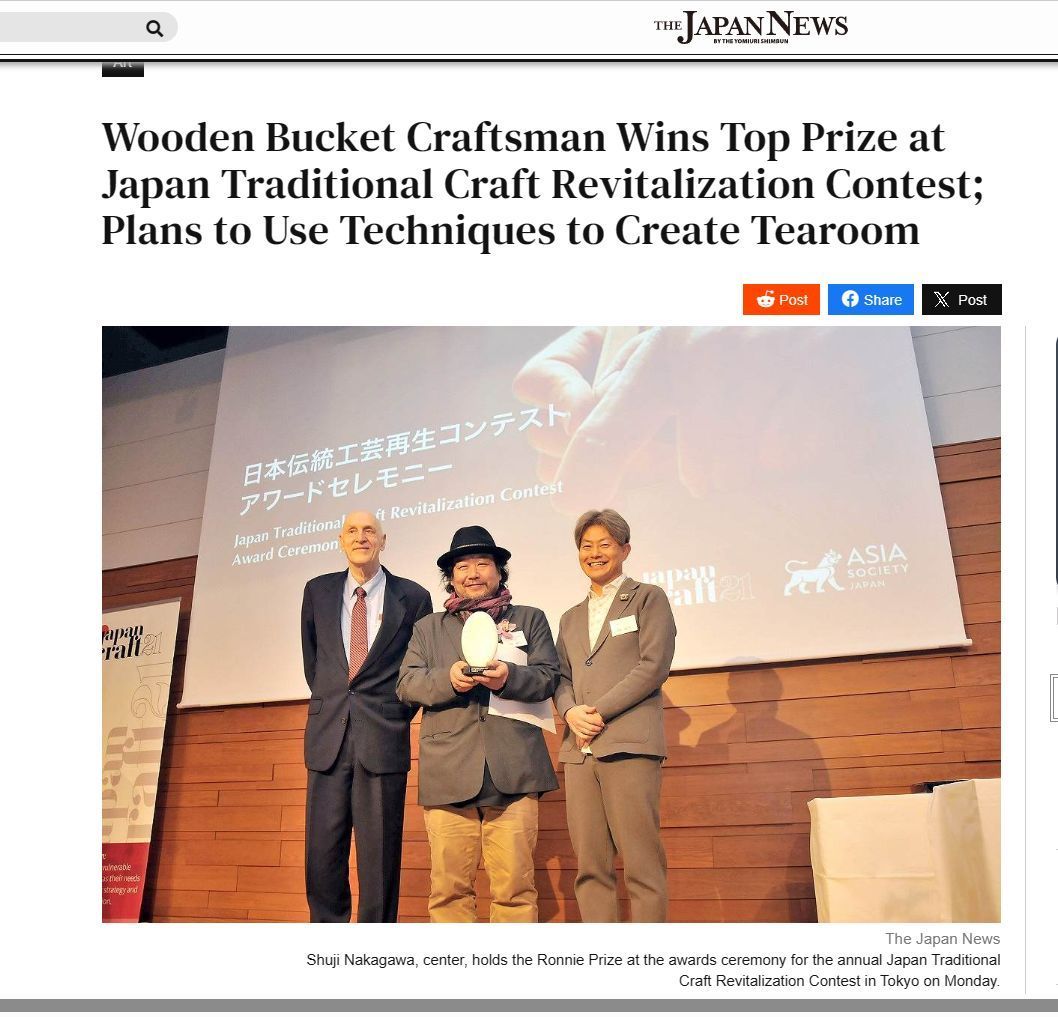

Ronnie Prize 2025 — Award Announcement

The 2025 Ronnie Prize has been awarded to Riku Matsuzaki for his work with Kyo-ai (Kyoto indigo).

His project was selected after careful review for its originality and future promise.

ロニー賞 2025年度 受賞者のお知らせ

2025年度ロニー賞の受賞者が決定しました。今年は、京藍(きょうあい)の再生に取り組む 松﨑 陸さん が選ばれました。

審査員による慎重な協議を経て選出された、意欲的で将来性のあるプロジェクトです。

@matsuzaki_riku

#japancraft21 #japan #kogei #craft #kyoai #京藍

【再建した珠洲焼の薪窯の火入れレポート】

令和6年1月の能登半島地震で倒壊した「珠洲焼」の薪窯が、たくさんの人の手によって再建され、昨日、令和7年12月25日に、火入れが行われました。JC21からも寄付させていただいたご縁から、火入れに立ち会いましたのでレポートします。

この薪窯は珠洲焼作家の篠原敬さんの「游戯窯(ゆげがま)」で倒壊したのは3度⽬でした。令和5年に2度⽬の倒壊。その後、再建したばかりだった薪窯は令和6年1月20日に火入れ予定だったところ、直前に正月の能登地震で三度目の倒壊。一度も火を入れることのないままの倒壊でした。この時の煉⽡を再利⽤して三度の再建となりました。

今回、焼かれている作品は、窯の再建をボランティアで手伝ってくれた200人が作った200個と篠原さんの作品200個。手伝ってくれた人には、各自100gずつ土を渡してそれぞれが成形しました。篠原さんは原点回帰の意味で珠洲焼のベーシックな形である壺などの作品を作ったそうです。

窯は29日か30日まで薪を入れ続け、最高1200度となります。温度計ではなく目で見て確認しますが、1200度の炎は白いのだそうです。その間、交代で火を見守ります。使用する薪は、なんと600束! 山積みにされた薪を「これを全部使います」とおっしゃっていて、記者一同驚きました。

火を止めるタイミングも、湿度や気温など気象状況に左右されます。早朝に朝日とともに気温が上昇していくのに合わせると、上昇気流が起こりやすいため、早朝に火を止めることが多いそうです。

珠洲焼は、鉄分を多く含む粘土で成形、高温で焼き上げ、火を止めて窯の口を塞ぎ酸欠状態にすることで、土に含まれる酸化鉄から酸素が奪われ、独特の深い灰黒色に変化します。そのとき、薪窯は「まるで生きているかのように拍動する」のだそうです。

黒板に書いてあるのは、この「游戯窯」での火入れの記録。前回は2023年の4月で64回だったので、今回は65回目。篠原さんは「ちょうど今、65歳なのでタイミングがいい」とおっしゃっていました。

篠原さんの「游戯窯」の名前の由来は、仏教※の言葉「園林遊戯(おんりんゆげ)」から。「子どもたちは遊ぶときに目的を持たない。目的意識は表現の幅を狭めてしまう。遊びは目的を持たないからこその広がりがある。そうした気持ちで珠洲焼と向き合いたい。そうはいかないこともありますが(笑)」ということだそうです。

「この窯の復興は、単なる窯の復興ではなく、珠洲市のみんなの精神の復興です。震災のおかげで、震災がなければ出逢うことのなかった人たちと交流できました。このご縁を大切にしたいし、さらに交流して広げていきたい」とおっしゃっていました。

※篠原さんは元・僧侶

【画像の説明】

1.火入れ後の炎

2.火をつける瞬間(マッチで火をつけておられます)

3.火の様子を見ながら薪をくべる篠原さん

4.火入れ前の薪窯

5.成形された珠洲焼の作品は焼く前は土色

6.窯は前回の倒壊を踏まえて補強されている

7.8.レンガで入り口を蓋していく様子

9.火をつける瞬間(動画)

10.火を様子を眺める篠原さん

11.黒板の記録を書き変える篠原さん(動画)

12.炎の灯りに照らされる篠原さん

#珠洲焼

#能登半島地震

#能登半島地震復興

#珠洲焼応援

#篠原敬

@nhkworldjapan にてバイメルが出演いたします。ぜひご覧ください。

Foreign Residents: Infusing New Life into Tradition

Many foreigners make Kyoto their home and bring innovation to traditional culture. Their creativity and global perspective spark revitalization and inspiration as they breathe new life into the city.

- Fabric made by a kimono producer who enjoys support from American Steve Beimel.

On Air Schedule

December 25, 2025. 09:30 - 09:58 / 14:30 - 14:58 / 19:30 - 19:58

December 26, 2025. 00:30 - 00:58 / 06:30 - 06:58

#nhk #nhkworld #nhkworldjapan

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Research about Traditional Japanese Crafts】

きみがらスリッパ Kimigara Slippers

Kimigara slippers are made in Aomori Prefecture. Towada City in Aomori Prefecture has been a horse-producing region since the Heian period. “Kimigara” means “corn skin” in Aomori’s dialect, and they produced Kimigara slippers to reuse the skin of dent corn, which is a crop to feed horses. The lightness of the material makes it cool in the summer and warm in the winter.

古くは平安時代から青森県十和田市は馬産地でした。「きみがら」とは青森の言葉で「とうもろこしの皮」のことを意味し、馬の飼料用作物であるデントコーンの皮の再利用のため、きみがらスリッパを製作してきました。とても軽いため、夏は涼しく冬は足になじみ暖かいのが特徴です。

織物・染色品<Textile>

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Chikako IWANAGA

Persimmon Tanning Dye Washi Paper / Hyogo

Her vision is to launch the commercial production of a durable, water-resistant, animal-free, and sustainable leather substitute made from Japanese mulberry-based washi paper treated with persimmon tannen, and expand her Hyogo-based grassroots community mulberry cultivation project to other rural areas around Japan.

@kamiyahyogo

#japancraft21 #japan #kogei #craft

1.The washi paper used is called Sugihara-gami. This renowned paper is produced in Taka Town, Hyogo Prefecture, and is a designated Important Intangible Cultural Asset of Hyogo Prefecture.

2.Wringing out the persimmon tannin-soaked washi, any remaining excess dye is removed with a brush, and the material is carefully smoothed to prevent unevenness.

3.Several coats of persimmon tannin are applied, followed by sun drying and mordanting to fix the color. Next it is rinsed thoroughly in water. Washi which is treated with persimmon tannin is very durable and does not tear even when vigorously manipulated.

—

The craft is a leather substitute created by treating handmade, paper-mulberry bark-based Japanese washi paper and with persimmon tannin from green-harvested persimmons. The paper is created by scooping up mulberry bark fibers sulution. After the fruit is crushed, the resulting liquid is fermented between several months to several years fermenting it for several months to years, and pressing it to extract the tannin-rich liquid. This liquid is known as kakishibu, which provides antibacterial, water-resistant, and strengthening properties. Konnyaku starch powdes defive fom a rook ida is often to increase durability and resistance to water damage.

@kamiyahyogo

#japancraft21 #japan #kogei #craft

After staining with red bengara, a natural Japanese pigment, additional coats of non-aged persimmon tannin are applied. This preserves the red bengara color, a process not possible with persimmon alone.

The persimmon tannin color deepens and becomes richer over time.

—

The craft is a leather substitute created by treating handmade, paper-mulberry bark-based Japanese washi paper and with persimmon tannin from green-harvested persimmons. The paper is created by scooping up mulberry bark fibers sulution. After the fruit is crushed, the resulting liquid is fermented between several months to several years fermenting it for several months to years, and pressing it to extract the tannin-rich liquid. This liquid is known as kakishibu, which provides antibacterial, water-resistant, and strengthening properties. Konnyaku starch powdes defive fom a rook ida is often to increase durability and resistance to water damage.

@kamiyahyogo

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

名古屋節句飾 NAGOYA-SEKKU-KAZARI

Nagoya Sekku Kazari are essential festival decorations celebrating a child's birth and growth, featuring dolls, celebratory flags, and paper-covered lanterns. Blending eastern and western styles, Nagoya's craftsmanship rivals that of Kyoto and Tokyo, with unique touches like large carp streamers and lanterns made from local materials like Kiso wood and Mino washi paper. Originating in the Edo period, these crafts grew in popularity, and by 1916, Nagoya's techniques surpassed Kyoto's. Today, Nagoya Sekku Kazari continues to be produced in Aichi and Gifu, honoring tradition and regional artistry.

名古屋節句飾は、3種類の工芸品「人形・幟旗(のぼりばた)類・雪洞」から成ります。人形は,京都と東京という二大産地に拮抗するとともに、東西の折衷様というべき様式が特徴です。幟旗類は,他所に見られない名古屋独特の大幟や腹部を鮮やかな黄色とした「黄腹の鯉」が特徴です。雪洞は美濃和紙、小原和紙などの良質の和紙や、木曽檜、松などの木工素材が豊富で折りたたみ不可など形状変更のできない火屋(ホヤ)物、火屋物提灯などが特徴です。

人形・こけし<Doll and Kokeshi>

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Shuji NAKAGAWA

Oke Woodworking / Shiga

Our long-range vision is to broaden the concept of Japanese traditional wooden barrels (kioke), so this master craft genre will grow and flourish for at least the next 100 years. To that end, we have created a portable “Wooden Barrel Tearoom” that can be easily moved and assembled for indoor and outdoor events as well as for permanent installation.

@nakagawa_mkkg

@shuji_nakagawa

#japancraft21 #japan #kogei #craft

Assorted traditional and contemporary buckets.

—

The oke is a wooden bucket that has been used in Japan for daily domestic purposes such as bathing, storage and preparation of food for over 700 years. These durable cypress or cedar containers are made up of curved pieces of wood held in shape with metal hoops placed at the top and bottom, resulting in a seamless surface. The vertical wood grain used in construction enhances breathability and prevents warping and other deformation.

@nakagawa_mkkg

@shuji_nakagawa

#japancraft21 #japan #kogei #craft

Wooden stools made by traditional Japanese bucket construction.

—

The oke is a wooden bucket that has been used in Japan for daily domestic purposes such as bathing, storage and preparation of food for over 700 years. These durable cypress or cedar containers are made up of curved pieces of wood held in shape with metal hoops placed at the top and bottom, resulting in a seamless surface. The vertical wood grain used in construction enhances breathability and prevents warping and other deformation.

@nakagawa_mkkg

@shuji_nakagawa

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

三春駒 Miharu Goma

Miharu Goma is a wooden toy horse, originating from Miharu, Fukushima. These small, hand-carved horses were histori- cally crafted as good luck charms, symbolizing strength and prote-ction. Painted with vibrant colors and intricate patterns, Miharu Goma are cherished for their cultural significance and connection to Japanese folk traditions, often associated with festivals and prayers for safety, especially in travel.

福島県の城下町三春の伝統工芸品。日本三大駒の一つとしても知られています。平安時代の武官・坂上田村麻呂が、793年に蝦夷討伐の際に苦戦していたところ、どこからともなく現われた木馬に助けられたという伝説に由来する「高柴子育木馬」が発祥と言われ、子育てのお守りとされた一寸大の馬型木彫が原形です。「三春駒」の特徴は、すべて直線で造られていて美しい上品な完成された紋様にあることです。子宝・安産・子育てのお守りとして作られ、白駒は老後安泰・長寿のお守りとして作られています。

人形・こけし<Doll and Kokeshi>

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Toshiharu HISATSUNE

Kago Yuzen Dye / Ishikawa

Toshiharu Hisatsune is a renowned Kanazawa-based Kaga yuzen dyer with over 40 years of experience. He is known for his technical mastery and commitment to natural dyes, extracting colors from various sources including grapes, berries and cherry blossoms. Though natural dye derived from cherry tree wood just prior to blooming is fairly common in Japan, dye from cherry blossom petals is rare, since the blossoms are not known to produce strong color. Hisatsune, however, has been successful in producing brilliant pink shades from petals that naturally fallen to the ground. A lifelong innovator, he has successfully applied yuzen techniques to dyeing of wood, glass, gold leaf and recently developed ultra-think textiles in additional to traditional kimono silk. Hisatsune aims to transform the chemical-dye-dominated Kaga Yuzen process by reviving the natural dying culture that existed in Japan for hundreds of years, prior to the modern era. Working with university researchers, he is helping to develop new natural dyes that produce exceptional color with significantly reduced drying time, another effort to revitalize Kaga Yuzen for the 21st century.

@hisatsune_yuzen

#japancraft21 #japan #kogei #craft

A long sleeve furisode kimono where various detailed motifs have been applied with tiny brushes by way of a resist dye method. The lavender ground color was applied by a larger brush.

—

Yuzen is a unique, 400-year-old, labor-intensive textile dye process in which color is applied to fabrics using tiny brushes to produce solid colors, color gradation, or elaborate motifs. The result is a highly prized cloth with a rich artistic aesthetic, most often used in high-end kimono and accessories. The use of traditional, natural dyes in Yuzen declined drastically since the introduction of European chemical dyes in the late 1800s, during the industrial revolution.

@hisatsune_yuzen

#japancraft21 #japan #kogei #craft

【Zoom presentation】

December online presentation is "Chinese and Japanese Gardens: One Concept, Two Interpretations."

Though Chinese and Japanese gardens appear dramatically different, they share a surprisingly similar underlying format. Unlike the formal gardens of Egypt, Rome, and later Europe—which clearly display the imprint of human design—Chinese and Japanese gardens seek to capture an idealized vision of nature.

This presentation explores the shared elements that connect these two great traditions—including framing, transitions, water features, bridges, the borrowing or screening of scenery, and the placement of stones—and reveals how each interprets these elements through its own aesthetic lens.

・Date & Time:

ーNorth America West Coast: Monday, December 22, 5 pm

ーNorth America East Coast: Monday, December 22, 8 pm

ーJapan: Tuesday, December 23, 10 am

・Registration:

https://forms.gle/XkxjDnf7tudyAYJ38

Reserve your spot today and be inspired by the artistry already shaping Japan’s craft future!

Together we can ensure the survival of Japan's extraordinary master

craft culture for generations to come.

#japancraft21 #japan #kogei

Yuzen dye process, where color is being filled into shapes that were outlined with a removable resist.

—

Yuzen is a unique, 400-year-old, labor-intensive textile dye process in which color is applied to fabrics using tiny brushes to produce solid colors, color gradation, or elaborate motifs. The result is a highly prized cloth with a rich artistic aesthetic, most often used in high-end kimono and accessories. The use of traditional, natural dyes in Yuzen declined drastically since the introduction of European chemical dyes in the late 1800s, during the industrial revolution.

@hisatsune_yuzen

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

京七宝 Kyo Shippo

Kyo Shippo refers to cloisonne enamel work found in shrines and temples in Kyoto as well as cloisonne enamel work made in Kyoto. The city has a long history of cloisonne enamelware, dating back to the Momoyama period (16th century). Through the early Edo period (17th century), this craft was used extensively for sliding door handles, nail covers, and decorative metal fittings. In the Meiji era (19th century), Kyoto Prefecture invited a German chemist to develop a transparent glaze, which became the basis for modern cloisonné. Kyo-Shippo includes various techniques, such as wired cloisonné, transparent cloisonné, and the use of silver threads for intricate designs, and these techniques are used in a variety of applications, including furnishings, accessories, wall decorations, lighting fixtures, and crafts.

京七宝とは、京都の社寺に所蔵されている七宝や京都で作られる七宝のことを指します。京都の七宝の歴史は古く、桃山時代(16世紀)に遡ります。江戸時代初期(17世紀)には、襖の取っ手や釘隠し、装飾金具など、幅広く用いられました。明治時代(19世紀)には、京都府がドイツ人化学者を招き、透明釉を開発し、これが現代の七宝のベースとなりました。京七宝には、有線七宝、透七宝、銀糸を用いて繊細な模様を描くなど、様々な技法があり、調度品、アクセサリー、壁面装飾、照明器具、工芸品など、幅広い用途に用いられています。

金工品・石工品 ▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【参加者募集!】

「竹小舞」って知っていますか?

「たけこまい」と読みます。

日本の伝統的な工法で建てられた家の壁は「土壁」でできていますよね。

この「土壁」を作る際の下地となる骨組みのことを「竹小舞」と言います。細く裂いた竹や木を縦横に格子状に編み込み、わら縄などで固定したもので、この上に、土を塗り重ねていくことで土壁になります。

この竹小舞を、実際の建築現場で編む体験乃ワークショップを開催します。なかなか体験できない貴重な機会です。

ぜひ、ご参加ください。

申し込みは「NPO法人祗匠会」のアカウントより、プロフィールのリンク先のフォームから。

@shishokai_gion

#日本の伝統建築

#伝統工法

#伝統構法

#竹小舞を編む

#竹小舞を編む体験ができる

【Craft Leader】Team YN

Yang Hen Chen & Noriko Tsuiki

Textiles, Architecture / Fukuoka

Composed of the talented architect Yang Hen Chen and the brilliant weaving & textile designer Noriko Tsuiki, this team is creating a catalyst for craft revitalization utilizing various natural materials, including wood, bamboo, and textiles, in their work. Tsuiki is a master craftsperson who revived traditional Kokura-ori weaving in the 1980s, helping bring back the dense cotton weave with the high, leather-like gloss once the chosen fabric for samurai hakama trousers. Chen is an innovative architect with a visionary ability to reimagine the relationship between traditional crafts and interior architectural settings. Together, their team is changing the design landscape by incorporating newly interpreted forms of traditional crafts into contemporary architecture and interior settings.

#TeamYN #YangHenChen #NorikoTsuiki

#japancraft21 #japan #kogei #craft

Close-up of Kokura Ori weaving.

—

In Kokura-ori weaving, the arrangement of colored threads in the warp becomes stripes in the woven cloth. It was a dominant style for hakama trousers used by samurai families during the Edo period (1603-1868). After dying out just before WWII, it was revived by Noriko Tsuiki in 1984. With 2,300 warp threads jin a 35cm width (almost double the normal density), the technique uses cotton thread to achieve the texture and gloss of tanned leather. The striped patterns formed using naturally dyed threads are said to have been inspired by the natural scenery. Brought back to life in the present day, the refinement and artistry of Kokura-ori continue to evolve.

#TeamYN #YangHenChen #NorikoTsuiki

#japancraft21 #japan #kogei #craft

Interior installation of a YN collaboration in a commercial setting, a 3-dimentional folded wall tapestry using Kokura Ori woven cotton cloth.

—

In Kokura-ori weaving, the arrangement of colored threads in the warp becomes stripes in the woven cloth. It was a dominant style for hakama trousers used by samurai families during the Edo period (1603-1868). After dying out just before WWII, it was revived by Noriko Tsuiki in 1984. With 2,300 warp threads jin a 35cm width (almost double the normal density), the technique uses cotton thread to achieve the texture and gloss of tanned leather. The striped patterns formed using naturally dyed threads are said to have been inspired by the natural scenery. Brought back to life in the present day, the refinement and artistry of Kokura-ori continue to evolve.

#TeamYN #YangHenChen #NorikoTsuiki

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

村上木彫堆朱 Murakami Kibori Tsuishu

Murakami city, an old castle town located in the northern part of Niigata prefecture, has long been a producer of high-quality natural lacquer. The tradition of Murakami woodcarving tsuishu was established during the Edo period. Artisans carve patterns such as flowers and birds into the wood, then apply layers of natural lacquer. After the top coat is applied, a matting process is carried out, and detailed carving is used to enhance the design. The matte finish allows the color and luster of these lacquerware pieces to increase with use. Today, Murakami woodcarving tsuishu is attracting attention as a unique artistic craft.

村上市は新潟県の北部に位置する古い城下町で、古くから良質の天然漆を多く産出していたことから、江戸時代に「村上木彫堆朱」の技法が確立しました。木地に花や鳥などの模様を彫刻し、天然の漆を塗り重ね、上塗り後に艶消しという工程を行い、表現を豊かにするために毛彫りを施します。艶消し仕上げを行うことで、使い込むほどに色艶が増して、味わい深い漆器となるのです。村上木彫堆朱は芸術的に特色ある工芸品として注目されています。

漆器<Lacquer>

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Shirayama Concept

Naruhito TOKUMARU

Oke Woodworking / Kagawa

Finely crafted Japanese cedar oke (barrels and buckets) were once found throughout Japanese daily life and culture in numerous variations, but in recent years these beautiful vessels have been steadily replaced by cheap, plastic substitutes. Led by Naruhito Tokumaru, the Shirayama Concept team, however, aims to create a new tradition of oke implements for everyday life which embody the beauty of Japanese craftsmanship. Through thoughtful design, production, and marketing, this unique team is utilizing domestic lumber, restoring the sustainability of local forests, and revitalizing an important craft tradition as it works to achieve the vision of “at least one oke in every household.”

@shirayama_concept

#japancraft21 #japan #kogei #craft

Finely crafted Japanese cedar oke (barrels and buckets) were once found throughout Japanese daily life and culture in numerous variations, but in recent years, these beautiful vessels have been steadily replaced by cheap plastic substitutes. These durable cypress or cedar containers are made up of curved pieces that are pressed together in a seamless surface. The vertical wood grain used in construction enhances breathability and prevents warping and other deformation.

@shirayama_concept

#japancraft21 #japan #kogei #craft

Finely crafted Japanese cedar oke (barrels and buckets) were once found throughout Japanese daily life and culture in numerous variations, but in recent years, these beautiful vessels have been steadily replaced by cheap plastic substitutes. These durable cypress or cedar containers are made up of curved pieces that are pressed together in a seamless surface. The vertical wood grain used in construction enhances breathability and prevents warping and other deformation.

@shirayama_concept

#japancraft21 #japan #kogei #craft

【Craft Leader】Daigo ADACHI + Taichiro TAKAMATSU

Textile Dye and Fashion Design / Yamagata

Textile dye master Daigo Adachi and clothing designer Taichiro Takamatsu intend to launch a new brand of one-of-a-kind, timeless clothing, based on the concept of "luxury by the human hand," the essence of craftsmanship.

@daigoadachi @taichiro_takamatsu

#japancraft21 #japan #kogei #craft

Folding and stitching process in itazome clamp dying

—

Itajime Shibori is a textile dyeing technique that came to Japan along the Silk Road in the 700s, involving a resist process where the edges of folded cloth being squeezed within securely bound, variously-shaped blocks, are exposed to liquid dye, resulting in many diverse patterns, whereas the squeezed part resist the dye completely.

@daigoadachi @taichiro_takamatsu

#japancraft21 #japan #kogei #craft

Long, formal sheer silk dress, dyed by itazome (board clamped) shibori technique

—

Itajime Shibori is a textile dyeing technique that came to Japan along the Silk Road in the 700s, involving a resist process where the edges of folded cloth being squeezed within securely bound, variously-shaped blocks, are exposed to liquid dye, resulting in many diverse patterns, whereas the squeezed part resist the dye completely.

@daigoadachi @taichiro_takamatsu

#japancraft21 #japan #kogei #craft

【Craft Leader】Junji KAGATA

Bamboo / Kyoto

4th generation Kyoto bamboo dealer, Kagata is developing well-designed and appealing, high-quality decorative motif bamboo products for architectural installations, using the rarefied varieties of bamboo and bamboo craftsmanship of Kyoto, while working to save age-old craft methodolgy for future generations.

#JunjiKAGATA #takehei

#japancraft21 #japan #kogei #craft

A typical bamboo fence as a guard wall or a decorative object for a Kyoto's machiya house.

—

Over 100 different types of bamboo are available at Takehei’s large storage facility. Varieties range from common, conventional bamboo to rare and exotic types, some up to 200 years old. These various bamboos are used in both interior and exterior architectural installation, craft making and art.

#JunjiKAGATA #takehei

#japancraft21 #japan #kogei #craft

Partation using antique smoked-bamboo strips.

—

Over 100 different types of bamboo are available at Takehei’s large storage facility. Varieties range from common, conventional bamboo to rare and exotic types, some up to 200 years old. These various bamboos are used in both interior and exterior architectural installation, craft making and art.

#JunjiKAGATA #takehei

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

笠間焼 Kasama Yaki

Kasama Yaki is a form of stoneware produced in the area around the city of Kasama, Ibaraki prefecture. This stoneware has long been considered a traditional souvenir of visiting Kasama Inari shrine (one of Japan's three major Inari shrines). Kasama Yaki has a strong finish which is produced with fine grained clay called gairome clay. Because of its strength and stain resistant feature, it is used for kitchenware such as water jugs, tea canisters and other daily used items. As gairome clay has a high iron content and turns brown after firing, it is more common to use decorating techniques such as dripping or overlaying glaze. In addition to a great diversity of decoration techniques, artisans are encouraged to develop their individuality on Kasama ware pieces without the constraints of tradition and formalities. Today, Kasama ware is used in flower vases, household ornaments, and art pieces. Potters continue to maintain a high level of quality that has been passed down ever since the Edo period (1603-1868).

茨城県笠間市周辺で作られる陶器のこと笠間焼の歴史は江戸時代中期、安永年間(1772~1781年)から始まります。日本三大稲荷の一つである笠間稲荷神社の参拝みやげとして古くから用いられてきました。笠間焼の特徴は、粘りがあり細かい粒子の蛙目粘土(がいろめねんど)で作られる丈夫な仕上がりです。丈夫なうえに汚れにも強く、水がめや茶壺など台所用品をはじめ日常で使用する雑器などに多く使われています。決まった形式がなく、種類やデザイン・スタイルが多種多様であり、作家・窯元それぞれの自由な作風が楽しめます。

陶器<Ceramics>

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Yuichi HIROSE

Edo Komon (Tokyo Style Stencil Dye) / Tokyo

It is my intention to revitalize silk stencil dying for generations to come with an advanced technique using newly designed, hand-made stencils that are superimposed onto antique Edo-period (1604-1848) stencils, resulting in dynamic new patterns.

—

Born in Tokyo in 1978, Yuichi HIROSE is a 4th-generation master stencil dyer, living and working in the same house in Tokyo as his great-grandfather did. In addition to his passion for surfing, he competed in the Sydney Olympics in 1980 in windsurfing. After graduating from university, he began his work as a traditional stencil dyer, fulfilling his dream of eventually taking over the family business. He has long held the vision of introducing Edo komon stencil dyeing around the world, and has been actively participating in exhibitions in Japan and abroad to that end, as well as by launching his brand of Edo komon-dyed silk stoles called “comment?”

@yuichi.hirose

#japancraft21 #japan #kogei #craft

Hirose’s 100-year-old stencil dye studio.

—

This traditional Japanese stencil dyeing technique, known for tiny, finely detailed patterns, dates back to the 1100s. The large and striking motif patterns applied to samurai armor and equipment in those early years eventually evolved into the small, refined designs we know today. Beginning in the 1600s, the dye technique was used to adorn the formal clothing of elite samurai, with unique patterns and colors representing each feudal clan that helped establish their clan identity and loyalty. When the Shogun government imposed laws restricting the wearing of ostentatious clothing among the increasingly wealthy merchant class, people avoided the laws by showing off their wealth through the subtlety and impeccable craftsmanship of Edo Komon. Japanese stencil dyeing profoundly influenced the development of French Silk Screen and European printed textiles.

The Edo Komon process begins with hand-carved stencils from Japanese washi paper that are treated and aged with persimmon tannin to increase their durability and longevity. One stencil can be used to dye up to 20 kimono. A paste made from rice and lime is applied through stencils onto fabric and acts as a resist to the textile dye that is later applied. The fabric is then steamed to set the dye evenly before the excess dye is removed through washing. Edo Komon dyers are known for their impeccable precision in seamlessly dying a 13-meter roll of silk by repeatedly moving the small paper pattern up to ninety times to complete a work,

@yuichi.hirose

#japancraft21 #japan #kogei #craft

Hirose shown standing over a long traditional work table in his family’s 100-year-old studio in Tokyo, over which he stencil dyes a 12-13 meter roll of silk, over and over, less than 30 cm at a time.

—

This traditional Japanese stencil dyeing technique, known for tiny, finely detailed patterns, dates back to the 1100s. The large and striking motif patterns applied to samurai armor and equipment in those early years eventually evolved into the small, refined designs we know today. Beginning in the 1600s, the dye technique was used to adorn the formal clothing of elite samurai, with unique patterns and colors representing each feudal clan that helped establish their clan identity and loyalty. When the Shogun government imposed laws restricting the wearing of ostentatious clothing among the increasingly wealthy merchant class, people avoided the laws by showing off their wealth through the subtlety and impeccable craftsmanship of Edo Komon. Japanese stencil dyeing profoundly influenced the development of French Silk Screen and European printed textiles.

The Edo Komon process begins with hand-carved stencils from Japanese washi paper that are treated and aged with persimmon tannin to increase their durability and longevity. One stencil can be used to dye up to 20 kimono. A paste made from rice and lime is applied through stencils onto fabric and acts as a resist to the textile dye that is later applied. The fabric is then steamed to set the dye evenly before the excess dye is removed through washing. Edo Komon dyers are known for their impeccable precision in seamlessly dying a 13-meter roll of silk by repeatedly moving the small paper pattern up to ninety times to complete a work,

@yuichi.hirose

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

塩沢紬 Shiozawa Tsumugi Silk

Shiozawa tsumugi is a silk textile produced in the former town of Shiozawa (now a part of the city of Minamiuonuma), Niigata prefecture. This craft is notable for using kasuri patterns. These patterns include the finely detailed T-shaped pattern or ka gasuri, a cross pattern or juji gasuri, and a tortoise shell pattern also called kikkou gasuri. The fabric is a single base color in cool tones, mostly navy blue, black or white which combined with a black kasuri pattern, possesses an elegant appearance.

塩沢紬(しおざわつむぎ)は、新潟県南魚沼市周辺で作られている織物です。江戸時代中頃に、長年織られてきた越後上布の技術を応用して生まれたのが塩沢紬です。経糸を合わせて作り出される非常に細かい蚊絣(かがすり)といわれる模様や十字絣(じゅうじがすり)、亀甲絣(きっこうがすり)などの絣模様が特徴です。

織物・染色品<Textile>

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Toshihiko INOUE

Paper Mounting / Kyoto

Traditional mounting of scrolls, folding byobu standing screens and fusuma paper doors is a complex, age-old master craft using natural materials, that is often overshadowed by the artworks they present. Inoue is meeting the needs of changing markets by introducing innovative uses for his traditional methodology. His works, created for use both domestically and abroad, include re-purposing the bouzu fusuma* for modern living spaces, easy-to-install and repair washi paper walls and drop ceilings in imaginative configurations, and collapsible paper work-cubicles and tearooms. Inoue aims to both heighten appreciation of Japanese crafts and culture, and work to regenerate the natural materials and techniques for producing them.

*Sliding paper doors featuring a Kyoto mounting style where the wooden door frames are tastefully hidden by wrapped washi paper, creating a crisp, contemporary feel.

@toshihiko.inoue.56

#japancraft21 #japan #kogei #craft

The repaired Edo period folding screen titled Moon is placed at the center, with a new folding screen on the right panel depicting the full moon's light using silver sand, and the left panel representing the dark night of the new moon with silver and black foil. This arrangement forms the Moon Trilogy.

—

Traditional mounting of scrolls, folding byobu standing screens and fusuma paper doors are part of a complex, age-old master craft using natural materials such as wood, various kinds of light and durable washi paper, rice glue and woven silk. Screens are made of folding panels that are connected by ingenious paper hinges that allow seamless folding in two directions. Each panel has a wooden outer frame and an inner wooden lattice structure that result in pockets of air, making it light and flexible. Up to ten layers of washi may be affixed to it with a rice paste glue. The front of the screen may have a border of woven silk brocade while the back may be covered with special paper or more woven silk. The screen’s frame is usually coated with black urushi lacquer with ornamental brass details added.

@toshihiko.inoue.56

#japancraft21 #japan #kogei #craft

The arrangement of bouzu fusuma (frameless sliding doors) using shike-ginu (a type of textured silk).

It can be assembled in just 10 minutes, allowing you to create a space surrounded by washi and silk textiles anywhere.

—

Traditional mounting of scrolls, folding byobu standing screens and fusuma paper doors are part of a complex, age-old master craft using natural materials such as wood, various kinds of light and durable washi paper, rice glue and woven silk. Screens are made of folding panels that are connected by ingenious paper hinges that allow seamless folding in two directions. Each panel has a wooden outer frame and an inner wooden lattice structure that result in pockets of air, making it light and flexible. Up to ten layers of washi may be affixed to it with a rice paste glue. The front of the screen may have a border of woven silk brocade while the back may be covered with special paper or more woven silk. The screen’s frame is usually coated with black urushi lacquer with ornamental brass details added.

@toshihiko.inoue.56

#japancraft21 #japan #kogei #craft

【Japan living arts】

Elizabeth Andoh – A Taste of Culture

Dear friends, colleagues and those who have expressed an interest in the FOOD & CULTURE of Japan:

包む TSUTSUMU… wrapping, enclosing, enveloping

In Japan, wrapping is an art, one with many “rules” about how to enclose objects. The degree of formality, the season, and the occasion (whether celebratory or conveying condolences) are some of the parameters that dictate the manner in which a package or envelope is wrapped.

Clothing also “wraps” or encloses the body. Japanese-style garments such as kimono are worn with the left side wrapped over the right side. The opposite (wrapping the right side over the left) is reserved exclusively for dressing the deceased for burial.

Perhaps the most versatile wrapper is a large, square cloth called furoshiki that can be used to transport all manner of packages and bundles… or can become elegant wrappers for gifts.

風呂敷 FUROSHIKI

Written with calligraphy for “bath” (furo 風呂) and “spread out” (shiki 敷) the word is rather curious. It seems the origins hark back to the Muromachi Period (1336-1573 AD) when Daimyo would spread out a cloth in which to wrap their clothing as they disrobed to bathe. That cloth began to be called furoshiki.

By the Edo Period (1603-1868) the use of furoshiki had become widespread as a convenient way for townspeople to carry all sorts of packages and bundles.

ーRead more here

https://japanlivingarts.com/

【Research about Traditional Japanese Crafts】

川尻筆 Kawajiri Fude

These brushes are made in Kawajiri Town, Kure City, and their production is said to have begun in the late Edo period with Ueno Yaekichi. Following the tradition of Kyoto brushes, their flexible tips are well-suited for cursive script, kana characters, and detailed Japanese paintings.

The common technique used is ‘nerimaze’ (blending of hairs), and a single craftsman handles the entire process from start to finish. While this method is not suitable for mass production, it requires advanced skills, resulting in brushes of exceptionally high quality.

呉市川尻町で作られており、江戸時代末期に上野八重吉が製造したのが始まりとされています。京筆の流れを汲み、しなやかな切っ先は、草書・かな・日本画の精密画などに適しています。

「練り混ぜ」という毛混ぜの技法が一般的で、最初から最後まで一人の職人が製作し、大量生産には向きませんが、反面、高度な技術を必要としていることから、出来上がった製品は高い品質の筆となります。

文具・和紙<Stationary and Washi Paper>

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Craft Leader】Shogo AKASHI

Fashion Design and Textile / Osaka

An apparel designer, Akashi is seeking to launch the OCACI clothing brand for contemporary lifestyles using traditionally made Japanese textiles that capture the warmth and heart of time-honored craftsmanship. Where domestic clothing production is currently at an all-time low of 2%, his work will ensure the survival of centuries-old textile processes in local communities throughout Japan and encourage rural revitalization.

@ocaci_official

#japancraft21 #japan #kogei #craft

This is an oversized band collar shirt made with original textiles that inherit the dyeing techniques of Kyoto artisans, infused with new sensibilities and creativity. Due to the hand-dyeing process, each shirt is a unique piece with no identical patterns. The design features delicate patterns and textures that can only be achieved through the craftsmanship of artisans, showcasing a camouflage pattern created with intersecting brush-dyed lines.

Category: Shirt

Item No.: OC-0022

Material: 100% Cotton

—

Akashi creates contemporary clothing with traditionally made Japanese textiles that capture the warmth and heart of time-honored craftsmanship and focus mainly on, but are not limited to, cotton.

@ocaci_official

#japancraft21 #japan #kogei #craft

This is a hand-dyed long-sleeve shirt crafted from original textiles that carry on the dyeing techniques of Kyoto artisans, enhanced with new sensibilities and creativity. Each shirt is one-of-a-kind due to the hand-dyeing process, ensuring that no two patterns are identical. This design features a distinctive stripe pattern created through brush dyeing.

Category: Shirt

Item No.: OC-0026

Material: 100% Cotton

—

Akashi creates contemporary clothing with traditionally made Japanese textiles that capture the warmth and heart of time-honored craftsmanship and focus mainly on, but are not limited to, cotton.

@ocaci_official

#japancraft21 #japan #kogei #craft

見て学べる京町家ツアー

昨年から毎月開催しています。

今回は、めずらしくまだ

残席ございます。

申込みはプロフィールの

リンクからお願いします。

見学する建築現場は

神社仏閣で知られる

石場建ての新築現場。

建築現場を見てみたい

建築科の学生さんや

伝統構法に興味のある

大工さんにも

お越しいただいています。

京町家に興味のある方

ぜひ、おすすめです!

#japancraft21

#NPO法人祗匠会

#祗園内藤工務店

#町家

#町家が好き

#京町家が好き

#町家暮らし

#町家めぐり

#町家めぐり好き

#町家めぐりしたい

#建築科

#大工さん

#町家大工

#石場建て

#石場建ての家

#町家ツアー

【Craft Leader】Yasuhiko KUSUNOKI

Silk & Leather / Kyoto

In a bold move, the third-generation head of a small weaving company in Kyoto’s rural Tango district, stepped away from modern mechanized weaving and re-adopted traditional wooden looms hand weaving, introducing the Kuska Fabric brand. This accentuates the “fluffiness, shade, and gentle texture created by the handiwork of artisans, alternating one right twist and one left twist of the weft yarn at a time” for which Tango Chirimen Crepe* has been known for 300 years.

Always innovating, Kusonoki now aims to create and market a line of craftsman-developed, hand-woven leather textiles, fully using Tango Chirimen Crepe* methodology and passing on the value of Tango woven textiles to the next generation.

*Crimped texture silk made in the Tango district

@kuska1936

#japancraft21 #japan #kogei #craft

Kusuka Tie

—

Kyoto’s Tango district has been producing woven silk fabrics since the 700s. For the past 300 years, they have been a center for white chirimen crepe silk production, which is used for kimono dyeing processes such as yuzen brush dyeing and stencil dyeing. Crepe is a plain weave product with a characteristic crimpled texture created with loosely twisted warp threads and weft threads tightly twisted 3000 - 4000 times per meter. Water scouring causes the fabric to shrink 30%, resulting in a lovely bumpy surface.

The production line of KUSKA, has evolved from producing white chirimen crepe for kimono dyeing to a high value-added process based on hand-weaving rather than automated weaving. Greater warmth and quality are achieved by hand weaving on old-fashioned wooden looms. The slow and gentle weaving pace places air into the weave and results in three-dimensional fabric that highlights the natural qualities of silk. Silk threads are shaped like translucent glass rods with a round, triangular cross-section and prismatic structure. Slow hand weaving increases the transmission and reflection of light through their structure, increasing the complex diamond-like brilliance that is emitted.

In addition to silk weaving, Kuska also produces a line of woven leather. While the long warp yarn on the loom may be silk, the weft is produced from thinly sliced leather. The result is a leather textile that can be used for shoes, bags, and other accessories.

@kuska1936

#japancraft21 #japan #kogei #craft

kuska fabric interacts with each material, and takes the fluffiness, shade, and gentle texture created by the handiwork of artisans, alternating one right twist and one left twist of the weft yarn at a time, to the future.

kuska fabric aims to be the one and only global brand “with the pride of 300 years of beautiful manufacturing of tango textiles.

—

Kyoto’s Tango district has been producing woven silk fabrics since the 700s. For the past 300 years, they have been a center for white chirimen crepe silk production, which is used for kimono dyeing processes such as yuzen brush dyeing and stencil dyeing. Crepe is a plain weave product with a characteristic crimpled texture created with loosely twisted warp threads and weft threads tightly twisted 3000 - 4000 times per meter. Water scouring causes the fabric to shrink 30%, resulting in a lovely bumpy surface.

The production line of KUSKA, has evolved from producing white chirimen crepe for kimono dyeing to a high value-added process based on hand-weaving rather than automated weaving. Greater warmth and quality are achieved by hand weaving on old-fashioned wooden looms. The slow and gentle weaving pace places air into the weave and results in three-dimensional fabric that highlights the natural qualities of silk. Silk threads are shaped like translucent glass rods with a round, triangular cross-section and prismatic structure. Slow hand weaving increases the transmission and reflection of light through their structure, increasing the complex diamond-like brilliance that is emitted.

In addition to silk weaving, Kuska also produces a line of woven leather. While the long warp yarn on the loom may be silk, the weft is produced from thinly sliced leather. The result is a leather textile that can be used for shoes, bags, and other accessories.

@kuska1936

#japancraft21 #japan #kogei #craft

【Research about Traditional Japanese Crafts】

東京琴 TOKYO Koto

The koto is a traditional Japanese musical instrument, primarily used for accompaniment. However, during the Edo period, a player named Yamada Kengyō created music that placed the koto at the center, leading to a flourishing production of the instrument in Edo. It is characterized by its loud volume and clear tone, producing a beautiful sound and rich resonance. Silk threads are used for the strings, and the body is typically made from paulownia wood. Skilled craftsmen meticulously adjust the instrument, considering the player's proficiency to achieve the ideal sound.

琴は和楽器の一つで、主に伴奏に使われていましたが、江戸時代に活躍した奏者・山田検校が琴を中心とした楽曲を作ったことで、江戸での生産がさかんになりました。特徴は音量の大きさと明瞭な音質で、美しい音色と余韻が生み出されます。素材は、弦には絹糸、胴体には桐などが用いられ、理想の音が出せるよう、奏者の力量を踏まえながら、職人による緻密な調整が施されます。

その他<Bamboo and Wood>

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject

#japancraft21 #japan #kogei #TraditionalJapaneseCrafts

【Zoom presentation】

Discover the beauty and ingenuity of Japan’s regional crafts in Part VI of JapanCraft21’s continuing exploration series. In this free, one-hour Zoom session, Steve Beimel will guide you through captivating traditions uncovered through JapanCraft21’s extensive research. Experience the artistry of woodworking, papermaking, textiles, dyeing, urushi lacquer, and more.

Enrich your understanding and take part in celebrating the timeless heritage of Japanese craftsmanship.

・Date & Time:

ーNorth America West Coast: Wednesday, November 5, 5 pm

ーNorth America East Coast: Wednesday, November 5, 8 pm

ーJapan: Thursday, November 6, 10 am

・Registration: https://forms.gle/KmUXHs3duuGraMQt9

#japancraft21 #japan #kogei

【Craft Leader】Yuriko TOKUNAGA

Furniture / Hyogo

Yuriko TOKUNAGA is the daughter and disciple of Toshio Tokunaga, an acclaimed master of woodworking and planesmanship. Seven years ago, after completing her university education and living for a year in France, she returned to her family home to apprentice with her father. This decision came naturally to her, having been born and raised in the atmosphere of a woodworker’s studio.

Yuriko entered the JapanCraft21 Traditional Craft Revitalization Contest in 2022 and became the first-place winner of the Ronnie Prize. Her contest application focused on three points: promoting and developing plane use in furniture making, the expansion of the Tokunaga concept of hand-crocheted cushions using Japanese washi paper, and the revitalization of Satoyama.**

A few years ago, she purchased a ricefield adjacent to her family’s property that bamboo had overtaken for the past 60 years. Through her perseverance and by attracting like-minded volunteers, she has restored the rice patty to its original condition. **An iconic Japanese agricultural valley surrounded by forested mountains and bamboo groves, where traditional rural life utilizes local nature in ecologically sustainable agriculture and cottage industry.

@tokunagafurniture

#japancraft21 #japan #kogei #craft #funiture

Cushioning is made from handmade ganpi washi paper that is cut into strips, twisted into paper cord, dipped into traditional persimmon tannin, and then twisted again. The cord is then crocheted into cushioning for this chair, resulting in comfortable, durable cushioning.

w 610 × d 820 × h 950 Mulberry

—

Washi paper from Ganpi - The washi paper-making process was introduced into Japan from Korea in the early 600’s. Though most washi is made from Kozo, the paper mulberry tree, a smaller amount is made from the Japanese native ganpi tree, a member of the Zingcho flower family. The slow-growing and slow-generating gampi tree is harvested in the wild. Unlike wood pulp paper, which requires the felling of trees, washi production from ganpi is sustainable since the same trees can be repeatedly harvested over time. The process begins with stripping the outer bark to access the inner bark, then soaking it in water to remove impurities. After boiling, the softened fibers are pounded and broken down into fibers, then placed in a vat of water. Adding a gelatinous fluid from a special plant root keeps the fibers in solution so they can more easily be scooped up on a bamboo screen and bound together. The screen size depends on the size of the paper being made. Rocking the screen causes the fibers to settle on the surface with a consistent thickness and facilitates the fiber bonding, resulting in strong and durable paper. Ganpi washi has shorter fibers, making it smooth and shiny. It is durable and insect-resistant and often used in art for painting.

@tokunagafurniture

#japancraft21 #japan #kogei #craft #funiture

US Ambassador's Residence Dining Chair

—

The Tokunaga studio is located in an idyllic satoyama.** The mood of the workspace is very meditative in that the process is done almost completely without electric tools. Their three-person workshop iincludes founder Yoshio Tokunaga, his long-term first disciple, and his daughter and heir apparent, Yuriko. Together, they produce original wooden furniture using the senior Tokunaga’s unique, highly refined hand-wood plane process that produces a natural wood sheen and luster that increases over time. Tokunaga collaborated with a steel blade craftsman to create a series of tiny, two-way planes central to their furniture-making concept. Convention planes are moved in one direction - pulled in Japan, pushed in the west. Tokunaga’s planes work in both directions, allowing them to work rhythmically and continuously, moving planes back and forth without having to interupt the flow to change directions. A consistent line resulting from smooth back-and-forth movements is subtly seen on the surface of their finished work, regardless of the angle at which it is viewed. Completely rejecting any use of sandpaper because it severely scars the surface of the wood, their plane process opens the “pores of the wood.” A clear comparison between planed and sandpapered wooden surfaces can be seen via microscope. Surprisingly durable, hand-crocheted cushioning made from Japanese washi paper by the Tokunaga Studio adds softness and texture to their furniture. The studio’s vision is to re-invigorate and expand the culture of traditional, local hand-plane finishing while ensuring the sustainability of essential domestic raw materials through reforestation and supporting the resurgence of local satoyama culture for future generations.

**An iconic Japanese agricultural valley surrounded by forested mountains and bamboo groves, where traditional rural life utilizes local nature in ecologically sustainable agriculture and cottage industry.

@tokunagafurniture

#japancraft21 #japan #kogei #craft #funiture

Feel the beauty and softness of conifer trees. Vibrato chair aligned like a sound with dynamics, imagined as if the forests are moving with the wind.

w 695 × d 530 × h 795

—

The Tokunaga studio is located in an idyllic satoyama.** The mood of the workspace is very meditative in that the process is done almost completely without electric tools. Their three-person workshop iincludes founder Yoshio Tokunaga, his long-term first disciple, and his daughter and heir apparent, Yuriko. Together, they produce original wooden furniture using the senior Tokunaga’s unique, highly refined hand-wood plane process that produces a natural wood sheen and luster that increases over time. Tokunaga collaborated with a steel blade craftsman to create a series of tiny, two-way planes central to their furniture-making concept. Convention planes are moved in one direction - pulled in Japan, pushed in the west. Tokunaga’s planes work in both directions, allowing them to work rhythmically and continuously, moving planes back and forth without having to interupt the flow to change directions. A consistent line resulting from smooth back-and-forth movements is subtly seen on the surface of their finished work, regardless of the angle at which it is viewed. Completely rejecting any use of sandpaper because it severely scars the surface of the wood, their plane process opens the “pores of the wood.” A clear comparison between planed and sandpapered wooden surfaces can be seen via microscope. Surprisingly durable, hand-crocheted cushioning made from Japanese washi paper by the Tokunaga Studio adds softness and texture to their furniture. The studio’s vision is to re-invigorate and expand the culture of traditional, local hand-plane finishing while ensuring the sustainability of essential domestic raw materials through reforestation and supporting the resurgence of local satoyama culture for future generations.

**An iconic Japanese agricultural valley surrounded by forested mountains and bamboo groves, where traditional rural life utilizes local nature in ecologically sustainable agriculture and cottage industry.

@tokunagafurniture

#japancraft21 #japan #kogei #craft #funiture

【Research about Traditional Japanese Crafts】

小久慈焼 Kokuji Yaki

Kokuji Yaki is from Kokuji city, Iwate prefecture. Unlike the Tsugaru Yaki previously mentioned, the Kokuji Yaki is known for its white and smooth finish that many describe to look like women’s skin. Kokuji Yaki has been around for more than 200 years, but it struggles to find a successor. The clay and glaze used for the Kokuji Yaki has not changed and are all made from locally sourced materials. Due to the low percentage of iron in the Kuji clay, it has to be smashed into fine pieces, then mixed with orthoclase and water to make the base. Pottery made from Kokuji Yaki is typically used as Sake vessels due to its signature shape. The typical design used for Kokuji Yaki is kata-kuchi, which has a narrowed, mouth-like spout on only one side so that it can be used to pour liquid.

小久慈焼のはじまりは約200年前、江戸時代後期に遡ります。主に日用の雑器として用いられ、八戸藩に納められたとの記録も残っています。やがてどの家庭にも必ずひとつふたつはあると言って良いほど地元に親しまれるようになり、明治時代には、この地を訪れた民藝運動家柳宗悦によって高く評価されました。時代は変わっていっていますが、原点である地元の粘土と釉薬を使うこと、それだけは変えずに守り続けています。

陶器<Ceramics>

▼Research about Traditional Japanese Crafts

https://encustomisehp.wixstudio.com/jc21researchproject